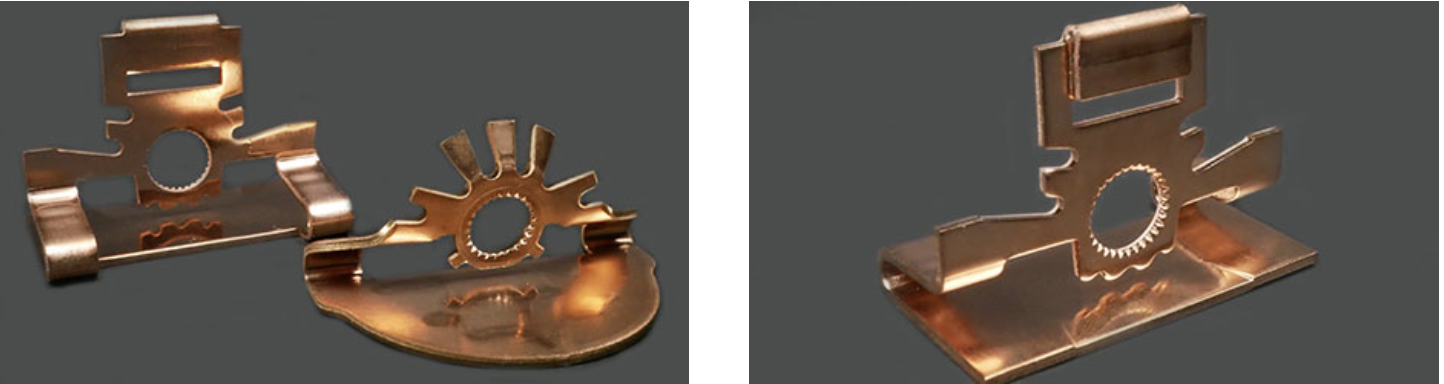

Copper Metal Stampings and Copper Alloys Metal Stampings

Copper and copper alloys offer a suite of infinitely recyclable materials providing many property combinations suited to a wide range of applications that facilitate and enhance our daily lives.

Copper’s performance can be expanded to suit many industrial applications by alloying: making a solid material out of two or more different metals. Good electrical and thermal conductivity, strength, ductility and excellent corrosion resistance are just some of the properties that copper and its alloys offer. Copper alloys are grouped into families, based on their composition.

There are more than 400 copper alloys, each with a unique combination of properties, to suit many applications, manufacturing processes and environments.

Pure copper has the best electrical and thermal conductivity of any commercial metal. Today, over half of the copper produced is used in electrical and electronic applications and this leads to a convenient classification of the types of copper into electrical (high conductivity) and non-electrical (engineering).

Common copper alloys used at New England Precision with copper content

greater than 99% include UNS

|

|

These alloys are heavily used in electronics and in engineering applications where high thermal conductivity, corrosion resistance, soldering, ductility, toughness, heat resistance, recyclability and aesthetics are important design properties.

Information from ASTM B152/B 152M specification: (Percentages based on weight)

- CDA 101 / UNS C10100: 99.99% Copper, Oxygen-free; often used in electronics

- CDA 102 / UNS C10200: 99.95% Copper, Oxygen-free without residual deoxidants

- CDA 110 / UNS C11000: 99.9% Copper

New England Precision, Inc. has a leading advantage over other tool and stamping companies by purchasing 5-7 million pounds of copper contained alloys every year. This affords us highly competitive fabrication charges by qualified leading mills. This buying power is significant because of the cost of metal stampings is in the material cost.

We pride ourselves on the ability to offer exceptional and innovative pricing programs. Your options include price/date of order, or firm fixed prices up to two years forward. We also entertain inventory stocking programs for those firms requesting just-in-time inventory levels. This includes stocking levels at our facility as well as off-site, vendor managed inventory. We are happy to fulfill any documentation requirements in order to qualify our products for ship to stock status, eliminating incoming inspections at your location.

In-House Tool and Die

Maintaining a tool and die facility in-house is crucial to today’s competitiveness in the stamping industry. With no dies in need of being sent out, New England Precision, Inc. is equipped to systematically tackle any troubleshooting first-hand and in the least amount of time, thus allowing for our continual success in getting product to our customers in the least amount of time.

Mission Statement

NEP’s mission is to successfully develop the necessary technology to design and build progressive tooling at the forefront of industrial demands. The tooling will be utilized along with material from qualified suppliers in an efficient systematic production facility to produce high quality stamped products.

The products will be sold to a diverse group of successful customers. Their loyalty will be earned by exceeding their expectation with quality and service. Partnerships will be formed with growth, opportunity and prosperity for our customers, our people and our community.

New England Precision Inc.

281 Beanville Road

Randolph, Vermont 05060

800-293-4112

© New England Precision Inc.

All rights reserved.

Site development: D2PWebDesign.